Case Study

Home » Case Study

AI Machine Vision (AIMV)

- Manual inspection of molded parts is time-consuming, costly, and prone to errors

- Automated defect detection using machine learning can improve the accuracy, consistency, and efficiency of the inspection process

- Simulates human inspection

- Reduces error

- Fast Inspection

- Defect detection

- Visualization using web application

- Feedback loop for improving future predictions

- Reduced Inspection time – 2 seconds per part (Down from 7 sec to 5 Sec)

- Savings of ~3.5 human days per month per machine

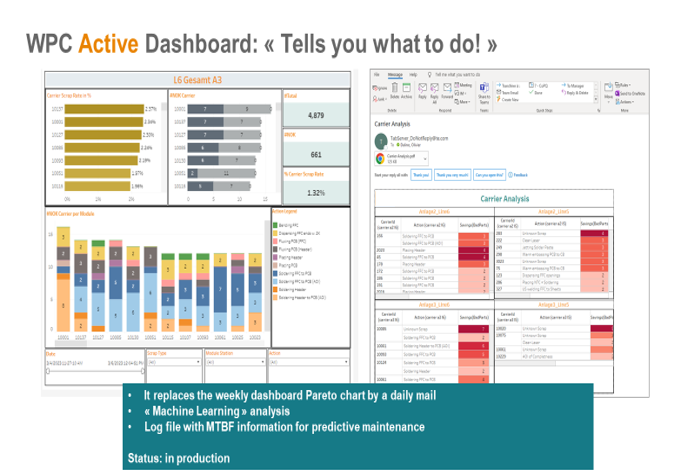

Carrier Analysis in

Assembly value-stream

- Identify the scrap rates associated with Carriers in Assembly lines to statistically determine, if removing a carrier and reworking/repairing it will bring in savings( reduced inline scrap parts).

- Email alert is triggered daily to let the plant team know which carriers are the troublemakers

- Simulates human inspection

- Reduces error

- Fast Inspection

- Defect detection

- Alerting operators

- € 1 Million considering 50% process effectiveness

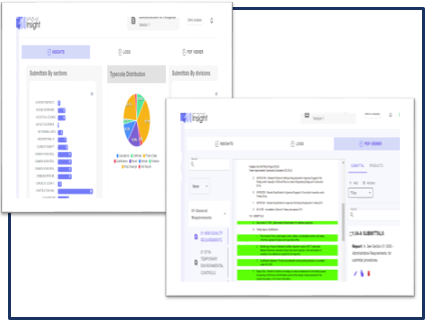

Submittal log extraction

- Before the construction of huge real-estate projects like data centres etc. Proper estimation of raw materials, shop drawings,warranties etc are documented. The documentations are huge and extracting information from the documents manually is labor intensive and error prone

- Text extraction from PDF documents

- Text summarization of extracted category descriptions

- Object detection

- Natural Language Processing

- Text summarization

- 400 hours of manual effort and 50% headcount reduction